2025-11-11

In recent years, BESS have become the cornerstone of the global transition to renewable energy sources. However, since each project has different requirements, ranging from voltage and capacity to the integration method, OEM BESS solutions emerged as flexible and cost-efficient options. But what does an OEM BESS Battery Energy Storage System mean, and why are energy developers and EPC companies turning to it?

OEM stands for Original Equipment Manufacturer. For BESS, this generally refers to the manufacturer of battery energy storage systems designed to be rebranded or integrated with other systems by other companies.

For example, a given energy company could be supplied by an OEM such as LZY Energy with custom LiFePO₄ battery modules, enclosures, and control systems while still maintaining its brand identity.

In other words:

The model enables quicker market entry and reduces R&D costs while ensuring reliable, quality components.

There are various advantages to partnering with an OEM.

The OEMs can also customize system voltage, energy capacity, and cooling design-air or liquid cooling-according to project needs, from residential 10kWh units up to 100MWh grid-scale containers.

Since OEMs specialize in mass production, the cost per unit of a battery and its components is much lower compared to bespoke systems built from scratch.

Pre-engineered OEM modules can reduce on-site commissioning time by up to 40%, especially in urgent projects involving renewable integration.

Top OEM BESS providers ensure compliance with UL, IEC, and CE standards to facilitate exports globally and the approval of local projects.

OEMs often provide long-term technical documentation, battery management system (BMS) upgrades, and software integration services.

The global BESS market is estimated to reach a value of USD 45 billion by 2030, driven by increasing demand from the OEM segment owing to competitive advantage in cost and modular flexibility.

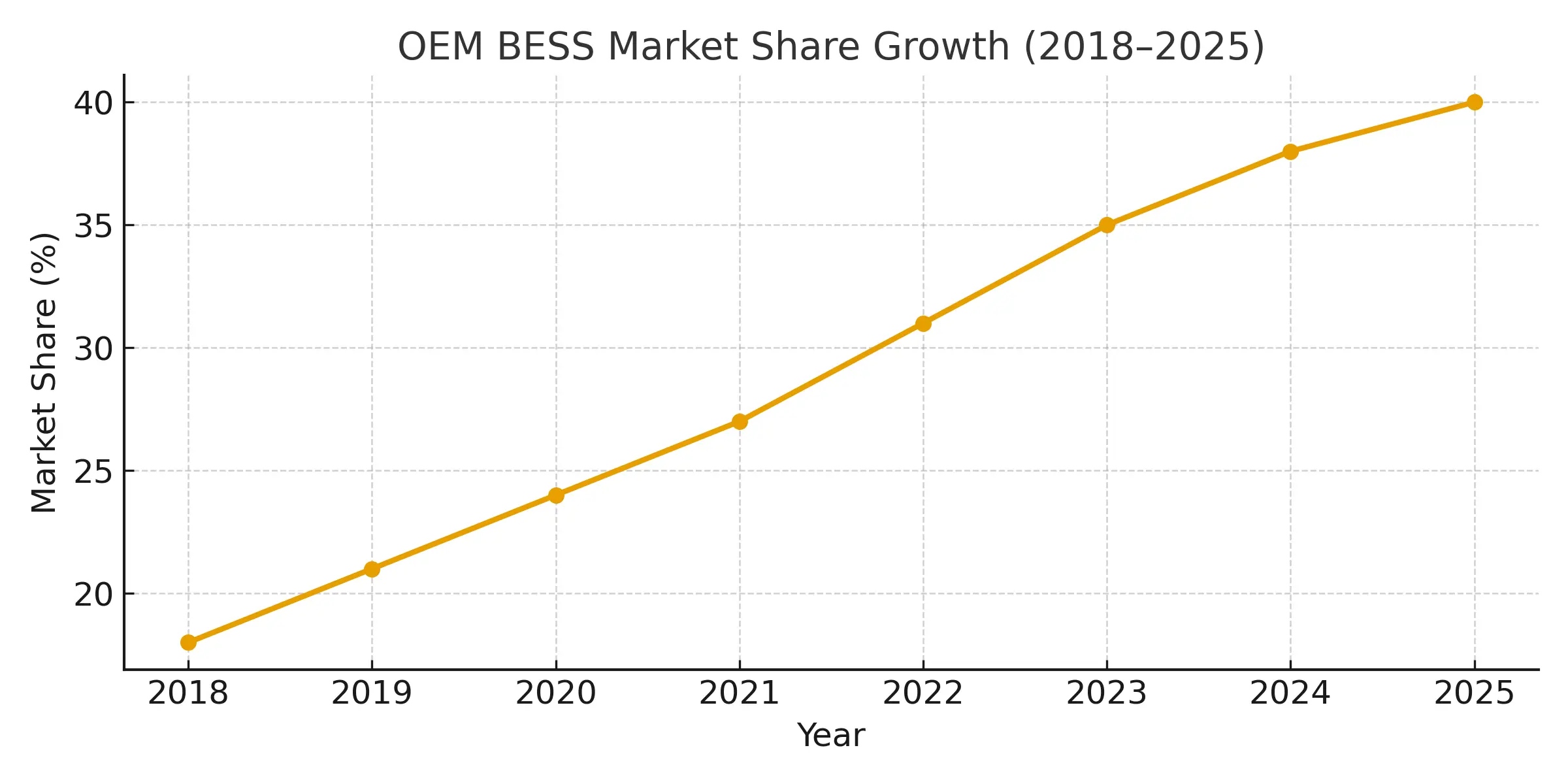

OEM-supplied BESS units now make up about 35% of total deployed systems, compared to just 18% five years ago, according to data from BloombergNEF.

OEM BESS Market Share Growth (2018–2025)

The following is a simple configuration example of how OEM systems are typically structured for a 1MW / 4MWh project:

| Component | Description | OEM Option Example |

| Battery Modules | LiFePO₄ cells (280Ah) | LZY Energy LFP280 Series |

| PCS (Power Conversion System) | 1MW bidirectional inverter | Integrated or external |

| Cooling System | Liquid cooling loop | Built-in |

| BMS & EMS | Remote monitoring and control | OEM firmware with open API |

| Container Size | 20ft standard enclosure | IP55, prefabricated |

| Cycle Life | >6000 cycles @ 80% DOD | 10-year warranty |

This kind of OEM system can be delivered as a turnkey container, ready for grid connection or microgrid deployment.

Having worked with several BESS manufacturers over the last years, I observe that the best OEM partners share a few common characteristics:

So, if you're choosing an OEM for your next project, always look beyond pricing; consider technical depth, after-sales service, and product traceability.

The OEM model will continue shaping the next decade of innovation in energy storage. As governments tighten safety standards and renewable penetration rises, demand for modular, certified, and affordable BESS solutions will further accelerate.

Emerging trends include:

In other words, OEM BESS systems are no longer just a "behind-the-scenes" solution; they're driving the scalability and affordability of global clean energy infrastructure.

European 4MWh Energy Storage Project

Shanghai Huijue Solar Carport Project

Small Commercial Energy Storage System Project for Singapore Manufacturing Companies

China Hunan Province Scenic Area Microgrid System Project

Northern Europe Commercial Center Outdoor Cabinet Industrial and Commercial Energy Storage System Project